Flameedgesimultaneouslyfillerwirerodmeltjointcoated

Read in the text.

1. …to melt metal and create a weld.

2. …advantages over other welding methods.

3. …using heat from a gas flame.

This is a story about welding materials and equipment.

1. Read and translate the text.

1. Welding current is conducted from the source of power to the arc by an insulated copper or aluminum cable. A very flexible cable is used between the electrode  holder and the welding machine. This cable is designed for welding service.

holder and the welding machine. This cable is designed for welding service.

For grounding the welding circuit, a less flexible, but equally wear resistant cable is used. The size of the cables used in welding depends upon the type of the material to be welded and the distance of the source of power.

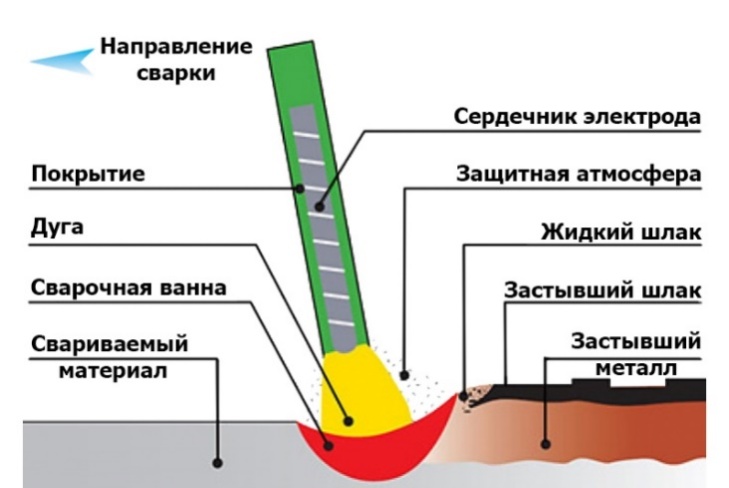

2. The electrode is an important component of the electric circuit. We know electrodes to be divided into consumable and non-consumable electrodes. Tungsten and carbon electrodes are non-consumable. In the case of carbon and tungsten arc welding a filler metal may be fed from aside to supply an additional metal to the molten pool. As for the consumable electrodes, they are produced in the form of metal rod or wire, and for this reason provide a filler metal.

3. All the consumable electrodes are divided into bare and coated electrodes. An important advantage of arc welding is in the protection that a special mineral flux composition provides for the molten deposit. It is know that metal electrodes for the covered with flux coatings produce stronger welded joints as compared with those made with bare electrodes.

4. As it was mentioned, the electrodes are held in a special device-an electrode holder. The electrode holder is a clamping device for holding the electrode and is provided with an insulated handle for the operation’s hand. It should be mechanically strong, light in weight and hold the electrode firmly in position during welding.

5. We know that the arc is very hot and therefore it throws off both light and heat. To protect the operator’s face and eyes from the direct rays of the arc it is necessary to use a face shield or helmet. These shield or helmets are produced of pressed insulating material black in colour. The shield should be light in weight and comfortable to the welder. Shields are provided with special welding coloured lens absorbing the infrared rays, special goggles are used by welder’s assistants, foremen, inspectors and others working near the welder.

6. In addition to the equipment and materials described above, there should be available steel brushes for cleaning welds, tools for removing scale and slag from the surface of the weld and other shop equipment. Of course, in any welding shop you may find the equipment for welding inspection.

Vocabulary

Insulate – изолировать

Flexible – гибкий

Wear resistant – износостойкий

Consume – тратить, расходовать

Consumable electrode – плавящийся электрод

Composition – смесь, состав

Impurity – примесь

Float – плавить на поверхности

Eliminate – устранять, предотвращать

Handle – рукоятка

Shield – щиток (сварочный)

Helmet – шлем

Coloured – цветной

2. Match the title to each paragraph.

1. Electrode flux coating.

2. Electrode and their types.

3. Cables and their features.

4. Other welding equipment.

5. Protection of welder’s face and eyes.

6. Electrode holders.

3. Answer the questions

1. What of electrodes are applied in welding?

2. How is a filler metal provided?

3. What is the difference between the two of cables?

4. What will you say about the electrode holder?

5. How are the welder’s face and eyes protected from welding rays?

6. Say a few words about welding helmet.

Find the words

Insulateflexiblewearresistantimpurityfloathandlehelmetcoloured

The welding technique.

Дата: 2019-02-25, просмотров: 578.