Unit 1. BASIC PRINCIPLES OF NUCLEAR ENERGY

1. Read and translate the text:

RATIONALE AND VISION FOR THE PEACEFUL USES OF NUCLEAR ENERGY

Nuclear energy has the potential to be a reliable, sustainable and environmentally friendly energy source that can contribute to the accessibility of affordable energy services in all interested countries for present and future generations. Any use of nuclear energy should be beneficial, responsible and sustainable, with due regard to the protection of people and the environment, non-proliferation, and security.

Match the following Russian and English equivalents.

5. Make your own sentences with these expressions:

a. due regard needs

b. should be based on

c. should apply to consideration

d. should be taken into account

Find in the text the all titles of IAEA publication. Put them in the table

| Guidance | Handbook | Others | Series | Standards |

Read the text again and answer the questions below.

1. What types of benefits, costs, and risks associated with different energy systems are there?

2. What does secure nuclear energy facilities, material, and operations against malevolent acts, including sabotage, theft and malicious misuse require?

3. What kinds of feedback do we need to strive for continual improvement of nuclear energy systems?

4. How could be achieved a high level of safety?

Choose the most important principle and explain why this particular principle was chosen

Write a short text and express your opinion. Remember that your opinion should be clear and supported with facts, reasons and examples.

Use the standard plane for such type of essays.

- express your opinion and give reasons to support your opinion

- state the opposite point of view and explain why you disagree with it.

- draw a conclusion

Unit 2. NUCLEAR REACTORS FOR INDUSTRIAL APPLICATIONS

1. Read and translate the text:

Nuclear energy can be used for various industrial applications, such as seawater desalination, hydrogen production, district heating or cooling, the extraction of tertiary oil resources and process heat applications such as cogeneration, coal to liquids conversion and assistance in the synthesis of chemical feedstock. A large demand for nuclear energy for industrial applications is expected to grow rapidly on account of steadily increasing energy consumption, the finite availability of fossil fuels and the increased sensitivity to the environmental impacts of fossil fuel combustion. With increasing prices for conventional oil, unconventional oil resources are increasingly utilized to meet such growing demand, especially for transport.

Nuclear energy offers a low carbon alternative and has important potential advantages over other sources being considered for future energy. There are no technological impediments to extracting heat and steam from a nuclear power plant. This has been proven for low temperatures (<200°C) with nuclear assisted district heating and desalination with an experience of approximately 750 reactor operation years from around 70 nuclear power plants. Detailed site specific analyses are essential for determining the best energy option. The development of small and medium sized reactors would therefore be better suited for cogeneration and would facilitate non-electric applications of nuclear energy. The possibility of large scale distribution systems for heat, steam and electricity supplied from a central nuclear heat source (e.g. a multiproduct energy centre) could attract and serve different kinds of consumers concentrated in industrial parks.

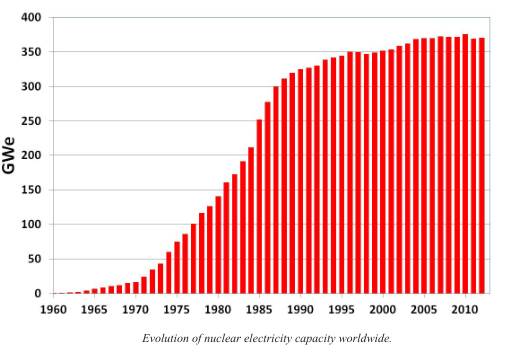

Look at this graf and explain how nuclear electricity capacity is changing worldwide

Generation IV reactors

With the overall goals established, GIF selected six concepts of advanced nuclear reactors for indepth study: GFRs, LFRs, MSRs, SFRs, SCWRs and VHTRs. Many studies investigate nuclear reactor modifications and progress required to produce cheap electricity and high temperature heat with efficient coupling with industrial process plants. With respect to the process heat temperature level that they offer, GCRs, MSRs and heavy metal cooled reactors appear to be the most promising technologies for higher temperature industrial processes such as hydrogen production. The various nuclear reactor technologies combined with thermally driven hydrogen production processes adaptable to nuclear reactors will complement, and not compete, in shaping the future nuclear based process heat and steam generation capabilities.

They report: that:

“...liquid metal and gas-cooled reactors can generate very high temperatures, which could be used to create new synthetic fuels for energy. This will be an innovative application of nuclear energy and can considerably expand its use. This is because the transportation sector is responsible for about a quarter of the total energy use and almost 99% of this is currently supplied by organic fuel. Nuclear power can penetrate this large market through use of electric cars and production of synthetic fuels such as methanol, ethanol and their derivatives; nuclear power can also be used for coal gasification, oil extraction and hydrogen production. All of these are being seriously considered in the 21st century. However, the infrastructure for use of these fuels needs to be created first, particularly in the case of environmentally ideal hydrogen fuel.”

Innovative applications are being explored with gas-cooled reactors because of their high temperatures. Cost-effectiveness is in general a crucial issue for non-electric applications of nuclear power. For some applications, however, close proximity of the power plant to a population centre is needed (to reduce energy and/or product transmission losses) and this requires further public acceptance. Some large applications also require the development of infrastructure — heat-distribution networks for district heating and water distribution systems (water pipes and pumps) for fresh water.

1. Water cooled reactor concepts

The three concepts of a water cooled reactor under consideration are the supercritical water cooled reactor (SCWR), the integral primary system reactor (IPSR), and the next generation Canada deuterium-uranium (CANDU-NG) reactor covering a wide range of thermal and power outputs and operating temperatures. The CANDU-NG reactor is designed for the medium power range of400-1200 MW(e) and the reference concept with 650 MW(e), CANDU-NG reactors are expected to combine the advantages of both CANDU reactors and pressurized water reactors.

Evolving from conventional LWRs, SCWRs operate at very high pressures, above the critical point, to allow for high coolant exit temperatures (up to 625°C) and high thermal efficiencies, Such a temperature level is suitable for medium temperature process heat applications. Since water systems operate at elevated pressures, intermediate systems will be needed to convert thermal energy to lower pressure fluids used in industrial applications. All of the water cooled concepts can be used for bottoming cycles that include district heating and desalination. The SCWR concepts proposed in GIF have thermal ratings of 900-3800 MW(th). The reference concept has a thermal power of 3575 MW(th) to produce 1600 MW(e) with a coolant exit temperature of 500°C.

The IPSR is a smaller pressurized water reactor system in which all major components are integrated in the pressure vessel. Thermal power envisioned is in the range of 30-300 MW(th). Examples for this class include the following:

— CAREM (Central Argentina de Elementos Modulares, Argentina);

— SMART (system-integrated modular advanced reactor, Republic of Korea);

— IRIS (International Reactor Innovative and Secure, international);

— IMR (integrated modular water reactor, Japan).

Of these IPSR concepts, SMART was the first to be granted a standard design approval.

2. Gas cooled reactor concepts

Gas cooled reactor (GCR) concepts include the pebble bed reactor (PBR), the prismatic modular reactor, the GFR and the VHTR. Helium pressures enhance the coolant capacity to transmit heat. The coated particle fuel used in the thermal spectrum concepts is capable of high bumups, and they are easily adjustable to a wide range of fuel cycles.

VHTRs comprise four concepts:

— GCRs aiming at ultrahigh helium temperatures of 1200-1500°C;

— Modular helium reactor (MHR);

— Annular PBR for the power range of 300-600 MW(th);

— Advanced High Temperature Reactor (AHTR), which is the reference concept.

Initially, the fuel cycle will be a once through cycle achieving very high burnups. The VHTR system has been primarily developed for non-electric process heat applications because of its ability to provide temperatures above 700°C. Operating in the cogeneration mode, the VHTR is capable of providing both electricity and process heat delivered at various temperature levels needed in industrial processes (e.g. in chemical and metal industries).

The GFR is a helium cooled, fast reactor with a fully closed fuel cycle, also with high helium exit temperatures

3. Liquid metal cooled reactor concepts

All concepts in the liquid metal systems category are driven toward medium to large scale electrical power production. Closed fuel cycles are employed for the purpose of maximizing the uranium resource utilization and minimizing the amount of high level radioactive waste.

These concepts have been optimized for power production. Most of these concepts operate with core outlet temperatures in the range of 500-560°C. One such concept, lead cooled with a plutonium-uranium-minor-actinide fuel in a nitride matrix, has a core exit temperature of 780°C, already in compliance with the needs of higher temperature applications. Several of the liquid metal systems including sodium cooled fast reactors (SFRs) could play a role using hybrid approaches to meet industrial temperature requirements. The medium temperature liquid metal systems could contribute to hydrogen production nuclear assisted steam reforming of natural gas and membrane reformers. However, the fact that the liquid metal concepts are designed to operate at relatively high thermal powers optimal for electrical power production could make them less attractive for alternative energy product applications.

The operation experience of SFRs in several countries has already been gathered. The GIF concepts are considered to cover a power range from smaller sized (150-500 MW(e)) modules to larger plants (up to 1500 MW(e)). They are designed for management of high level wastes, and the nominal outlet temperature is 550°C for all options. An intermediate sodium circuit is used between primary system and the tertiary steam cycle.

LFR systems use pure lead or lead-bismuth eutectic liquid as coolant. Plant sizes are in the range of 1200 MW(e) for a large plant and 50-150 MW(e) for a battery type. High coolant temperatures allow for process heat applications, including the production of hydrogen by HTSE. The battery system LFRs with their long life without refuelling (up to 20 years) are designed to serve as power sources in isolated locations or on small grids, and also can be used for distributed generation of electricity and other energy products. An example is the Secure, Transportable, Autonomous Reactor (United States of America) concept, with a size of 300-400 MW(th) and uranium-transuranic nitride fuel, which needs to be replaced every 15 years. A congenial variant is the Small, Sealed, Transportable, Autonomous Reactor (Japan) concept, with a smaller size of 45 MW(th)/20 MW(e). After a 20 year life without refuelling, the whole reactor unit is returned to recycle the fuel.

4. Non-classical reactor concepts for other energy missions

The three Generation IV concepts characterized as non-classical reactors are the MSR, the vapour core reactor (VCR) and the AHTR.

The MSR transmutates actinides while producing significant amounts of electricity. The power is nominally 2250 MW(th), although it is not limited by inherent reactor characteristics. With a nominal outlet temperature of 700°C, the efficiency is expected to be around 45%. The design pressure of the system is as low as 520 kPa to allow for pumping losses and hydrostatic head. MSR development is going in two directions:

- the first is a fuel that is a liquid mixture of sodium, zirconium and uranium fluorides flowing through graphite core channels;

- the second is a fuel that is kept in graphite prisms separate from the molten salt coolant.

A 5 MW(th) demonstration version is currently being developed at the Shanghai Institute of Applied Physics.

The VCR has the highest outlet temperature of the non-classical concepts. It operates with a UF4 fuel at sufficiently high temperatures to vaporize the fuel which is then uniformly mixed with the working fluid. The temperature is limited by reactor vessel and heat exchanger materials. The VCR has the primary mission to produce heat at very high temperatures for use either in efficient electricity generation (magnetohydrodynamic generation as topping cycle plus a conventional Brayton gas turbine bottoming cycle) or in the production of hydrogen and high grade process heat.

The AHTR is essentially a prismatic graphite moderated, molten salt cooled pool type reactor in the power range of 600-2400 MW(th).The molten salt coolant can be at temperatures of up to 1000°C in a non-pressurized reactor vessel. The thermal power is limited due to the need for passive heat removal in the event of a loss of coolant. The outlet temperature is similar to that of the VHTR and its upper limit mainly dictated by heat exchanger and reactor vessel liner materials rather than by temperatures of the coated particle fuel. Respective development and improvement of the materials could make the reactor attractive for industrial high temperature heat applications.

| Nuclear reactors | coolant | Power MWt | Temperature t0 | Pressure kPa | application | features |

| GFR | helium | 275 | 850 | electricity | Closed loop | |

| LFR | liquid metal | 50-1200 | 480-800 | electricity | lead, bismuth | |

| MSR | salt | 2250 | 700 | <520 | electricity | |

| SFR | liquid metal | 150-1500 | 550 | electricity | sodium | |

| SCWR | water | 900-3800 | 625 | 2210 | electricity | |

| VHTR | helium | 300-600 | >700 | electricity |

CONCLUSION

High temperature applications of nuclear energy, particularly for production of new fuels like hydrogen on a carbon dioxide emission free basis can have great potential for the future. The simplest and most near term application with very large market potential for small sized modular nuclear reactors is the generation of high quality steam for consumers in the chemical and petroleum industries

Unit 3. The International Reporting System for Operating Experience

1. Read and translate the text:

Incident reporting is an important aspect of the operation and regulation of all public health and safety related industries. Diverse industries, such as aeronautics, chemicals, pharmaceuticals and explosives industries, depend on operating experience feedback to provide lessons learned about safety.

The International Reporting System for Operating Experience (IRS) is an essential element of the international operating experience feedback system for nuclear power plants. IRS reports contain information on events and important lessons learned that assist in reducing the recurrence of events at other plants. The IRS is jointly operated and managed by the Nuclear Energy Agency (NEA) — a semiautonomous body within the Organisation for Economic Cooperation and Development — and the IAEA. For the system to be fully effective, it is essential that national organizations allocate sufficient resources to enable the timely reporting of events important to safety and to share these events in the IRS database.

Serious accident - Level 7

People and the environment

Major release of radioactive material with widespread effects on health and the environment, which requires the implementation and extension of planned countermeasures.

Major accident - Level 6

People and the environment

Significant release of radioactive material likely to require implementation of planned countermeasures.

People and the environment

Limited release of radioactive material likely to require implementation of some planned countermeasures.

Several deaths from radiation.

People and the environment

Minor release of radioactive material, with little likelihood of having to apply countermeasures under unless local food controls.

At least one death from radiation.

Major incident - Level 3

People and the environment

Exposure ten times the annual limit for exposure of workers.

Effect non-lethal of radiation health.

Defense in depth

Near accident at a nuclear power plant without provision of security pending application.

Lost or stolen of highly radioactive sealed sources.

Wrong delivery of highly radioactive sealed source without adequate procedures to manipulate.

Incident - Level 2

People and the environment

Exhibition of an audience above 10 mSv.

Exposure of a worker in excess of statutory annual limits.

Defense in depth

Significant failures in safety provisions, but without real consequences.

Finding of an orphaned sealed source of a device or packaging for the transport of highly radioactive, indicating security arrangements, there has been no impairment.

Inadequate packaging of a highly radioactive sealed source.

Deviations - Level 1

Defense in depth

Overexposure to an audience in excess of statutory annual limits.

Minor problems in safety components with significant defense measures pending application in depth.

Lost or stolen radioactive source, device or transport packaging of low activity.

The entire range of conditions for which an NPP is designed according to established design criteria, including all the national regulatory requirements, and for which damage to the fuel and release of radioactive material are kept within authorized limits, form the design basis of an NPP. Within the design basis, a number of unintended events are considered, including operating errors and equipment failures, whose consequences or potential consequences are not negligible in terms of safety. According to the probability of its occurrence and potential consequences, an event may be classified as an anticipated operational occurrence (also called a transient) or a design basis accident (DBA).

An accident occurring outside the NPP design basis is called a beyond design basis accident (BDBA). Such an accident may or may not involve degradation of the reactor core (leading to significant core damage). An accident involving core degradation (typically with core melting) is also called a severe accident.

Find Russian equivalents

1. Primary coolant system components

2. Reactor

2.1. Dimensions of main reactor components

2.1.1. Reactor head

2.1.2. Reactor vessel around inlet and outlet nozzles

2.1.3. Reactor vessel on the core level

2.1.4. Lower part of the reactor vessel

2.2. Masses of reactor components

2.3. Volumes in reactor vessel

2.4. Flow cross-sections in reactor

3. Core

4. Main circulation loop

5. Steam generator: primary side

6. Reactor coolant pump

7. Pressurizer systems

7.1. Pressurizer

7.2. Bubbler condenser tank

8. Make-up system

9. Emergency core cooling system

9.1. Passive emergency core cooling system

9.2. High pressure core cooling system

9.3. Low pressure core cooling system

Unit 1. BASIC PRINCIPLES OF NUCLEAR ENERGY

1. Read and translate the text:

RATIONALE AND VISION FOR THE PEACEFUL USES OF NUCLEAR ENERGY

Nuclear energy has the potential to be a reliable, sustainable and environmentally friendly energy source that can contribute to the accessibility of affordable energy services in all interested countries for present and future generations. Any use of nuclear energy should be beneficial, responsible and sustainable, with due regard to the protection of people and the environment, non-proliferation, and security.

Дата: 2019-04-23, просмотров: 325.