This is a difficult area and what is to be reported must be considered in the context of the client's needs. In particular, consideration must be given to the possible consequences and risks associated with a result that is close to the specification limit. The uncertainty may be such as to raise real doubt about the reliability of pass/fail statements. When uncertainty is not taken into account, then the larger the uncertainty, the greater are the chances of passing failures and failing passes. A lower uncertainty is usually attained by using better equipment, better control of environment, and ensuring consistent performance of the test.

For some products it may be appropriate for the user to make a judgement of compliance, based on whether the result is within the specified limits with no allowance made for uncertainty. This is often referred to as shared risk, since the end user takes some of the risk of the product not meeting specification. The implications of that risk may vary considerably. Shared risk may be acceptable in non-safety critical performance, for example the EMC characteristics of a domestic radio or TV. However, when testing a heart pacemaker or components for aerospace purposes, the user may require that the risk of the product not complying has to be negligible and would need uncertainty to be taken into account. An important aspect of shared risk is that the parties concerned agree on the uncertainty that is acceptable; otherwise disputes could arise later.

Conclusion

Uncertainty is an unavoidable part of any measurement and it starts to matter when results are close to a specified limit. A proper evaluation of uncertainty is good professional practice and can provide laboratories and customers with valuable information about the quality and reliability of the result. Although common practice in calibration, there is some way to go with expression of uncertainty in testing, but there is growing activity in the area and, in time, uncertainty statements will be the norm.

Say whether the following statements are true or false.

1. Laboratories are to evaluate uncertainty only when reporting is required.

2. The process of evaluation emphasizes those aspects of a test or calibration that produce the greatest uncertainty components.

3. Uncertainty evaluation can be done by any engineer who is familiar with measuring equipment.

4. It’s not complicated to take into account possible consequences and risks associated with a result

5. Using better equipment and control of environment ensures lower uncertainty.

6. The user should make a judgement of compliance for some products which is often referred to as shared risk.

7. Shared risk is not acceptable in the EMC characteristics of a domestic radio or TV.

8. An important aspect of shared risk is that the parties concerned agree on the uncertainty that is acceptable.

Make 5-7 questions to the text and discuss them in a group.

Make presentation to the topic “Measurement uncertainty”.

Unit 5

MEASUREMENT ERROR, ACCURACY AND PRECISION

Practice reading the following words.

Accurate, proceeding, uncertainty, hitherto, purpose, traceable, negligible, caliper, associate, micrometer, biases, precision, measuring.

In the science of measurement it is important to distinguish between measurement uncertainty and error, accuracy and precision. Are the notions related? Which way do they differ? Discuss in groups.

3. Read and translate the text.

TEXT A

Before proceeding to study ways to evaluate the measurement uncertainty, it is very important to distinguish clearly between the concepts of uncertainty and error. In the VIM, error is defined as a result of a measurement minus a true value of a measurand. In turn, a true value is defined as a value that is consistent with the definition of the measurand.

True value is equivalent to what hitherto we have been calling actual value.

In principle, a (true or actual) value could only be obtained by a ‘perfect’ measurement. However, for all practical purposes, a traceable best estimate with a negligible small uncertainty can be taken to be equal to the value of the measurand (especially when referring to a quantity realized by a measurement standard, such an estimate is sometimes called conventional true value). To illustrate this, assume that a rod’s length is measured not with a caliper, but with a very precise and calibrated traceable) micrometre. After taking into account all due corrections the result is found to be 9.949 mm with an uncertainty smaller than 1 µm. Hence, we let the length 9.949 mm be equal to the conventional true value of the rod.

Now comes the inspector with his/her caliper and obtains the result 9.91 mm.

The error in this result is then equal to (9.91 − 9.949) mm = −0.039 mm. A second measurement gives the result 9.93 mm, with an error of −0.019 mm.

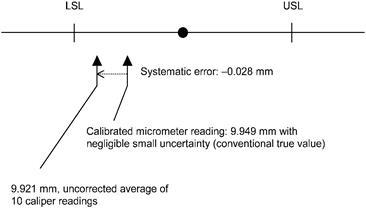

After taking a large number of measurements (say 10) the inspector calculates their average and obtains 9.921 mm, with an error of −0.028 mm (it is reasonable to write 9.921 mm instead of 9.92 mm, since the added significant figure is the result of an averaging process). The value −0.028 mm is called the systematic error; it is defined as the mean that would result from a very large number of measurements of the same measurand carried out under repeatability conditions minus a true value of a measurand (figure 1).

Figure 5.1. Systematic error

Figure 5.1. Systematic error

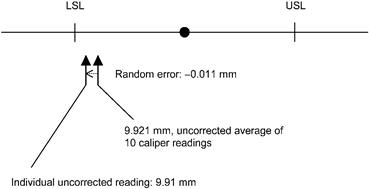

Return now to the individual measurement results. The first was 9.91 mm.

With respect to the average, its error is (9.91 − 9.921) mm = −0.011 mm. This value is called a random error; it is defined as a result of a measurement minus the mean that would result from a very large number of measurements of the same measurand carried out under repeatability conditions (figure 2).

Figure 5.2. Random error

Figure 5.2. Random error

The sum of the random error and systematic error constitute total error.

Error and uncertainty are quite often taken as synonyms in the technical literature. In fact, it is not uncommon to read about ‘random’ and ‘systematic’ uncertainties. The use of such terminology is nowadays strongly discouraged.

It is also important to define the related concepts of accuracy and precision.

The former is the closeness of the agreement between the result of a measurement and a true value of the measurand. Thus, a measurement is ‘accurate’ if its error is ‘small’. Similarly, an ‘accurate instrument’ is one whose indications need not be corrected or, more properly, if all applicable corrections are found to be close to zero. Quantitatively, an accuracy of, say, 0.1 %—one part in a thousand—means that the measured value is not expected to deviate from the true value of the measurand by more than the stated amount.

Strangely enough, ‘precision’ is not defined in the VIM. This is probably because many meanings can be contributed to this word, depending on the context in which it appears. For example, ‘precision manufacturing’ is used to indicate stringent manufacturing tolerances, while a ‘precision measurement instrument’ might be used to designate one that gives a relatively large number of significant figures. We take the term ‘precision’ as a quantitative indication of the variability of a series of repeatable measurement results.

Дата: 2016-10-02, просмотров: 286.